Overexertion is one of the biggest causes of injury in manual labour. It affects over 250,000 workers every year in the United States alone. However, using modern technology, we can aim to eliminate this issue. To solve the problem, we (Jason Yin and I) developed and created an active lower-body exoskeleton powered by pneumatic cylinders and controlled by a raspberry pi microcomputer with custom software. The goal of this device is to enhance mobility and provide mechanical assistance. The exoskeleton does so by manipulating the distance between the hip and the ankle which is electronically triggered from user inputs to our microcomputer, activating the pneumatic cylinders at specific timings through the exoskeleton's software. From testing, our mechanical assistance system provides 980N of additional lifting capabilities, all while under a 0.54s response time. Through the use of this tool, humans can reduce strain on their bodies, significantly reducing injury.

As civilization carries on growing to support its increasing

population, the need for manual work only increases as there are

more houses to build, packages to ship, and materials to move.

Nevertheless, along with that work, comes the risk of strain and

injuries on the human body: Every year in the United States, 255'000

manual work labourers suffer from an injury resulting from

overexertion.

The concerning number of injuries generally stems from pushing,

lifting, and carrying objects with improper technique. However, the

reason for the improper technique often isn’t due to lack of proper

training but rather due to the object being too heavy to use proper

form on, forcing workers to place themselves in harm’s way. Using

the incredible technological advancements humans have made, however,

we have received the ability to eliminate this problem by enhancing

the user's leg strength and mobility. Through the increase in

strength, the user can once again return to focusing on their form

knowing that they have the power to do so.

To solve the problem affecting millions of people worldwide, we came

up with an active lower-body exoskeleton that uses pneumatic power

to extend and retract the leg with a superhuman amount of force.

To supply additional power to the user to reduce overexertion

injuries, we developed a rough idea for an exoskeleton that

ultimately required four different systems: Frame, Air delivery,

Battery, and Control.

We would start by brainstorming the parameters required for each

system. Then, we would research different ways to achieve these

parameters through different methods. One reason why it was

important to find different solutions was due to finding the optimal

solution. For example, when designing, we had to decide on an

actuator type to power the exoskeleton. We had three possible

solutions (pneumatic, electric motor, and hydraulic) and with them,

we determined the best powertrain through calculations. In that

specific case, our calculations were to find the actuator with the

maximum power output, lowest electricity consumption, and minimal

weight.

Once we had ample research, we moved on to design. When possible, we

would model in a 3d virtual environment to best understand the

interactions of our design with other systems. Another benefit of

modelling was the available stress and displacement tests that would

inform us of any inadequacies.

Next, we consulted professors. Through this method, we would be

aware of any oversights we may have made and would be notified of

any better solutions.

Finally, we would choose the material to prepare for manufacturing.

Strength to weight ratio was always the focus. For example, we chose

Aluminum 6061-T6 for the material.

After all systems were completed and attached, we tested the

performance of the exoskeleton through different experiments to

optimize performance.

To find the most accurate sources of information, we focused on

receiving our knowledge from university research papers,

manufacturer datasheets, and when possible, patents. Through this

methodology, we were able to be confident that our solutions and

calculations would yield the best results.

How It Works:

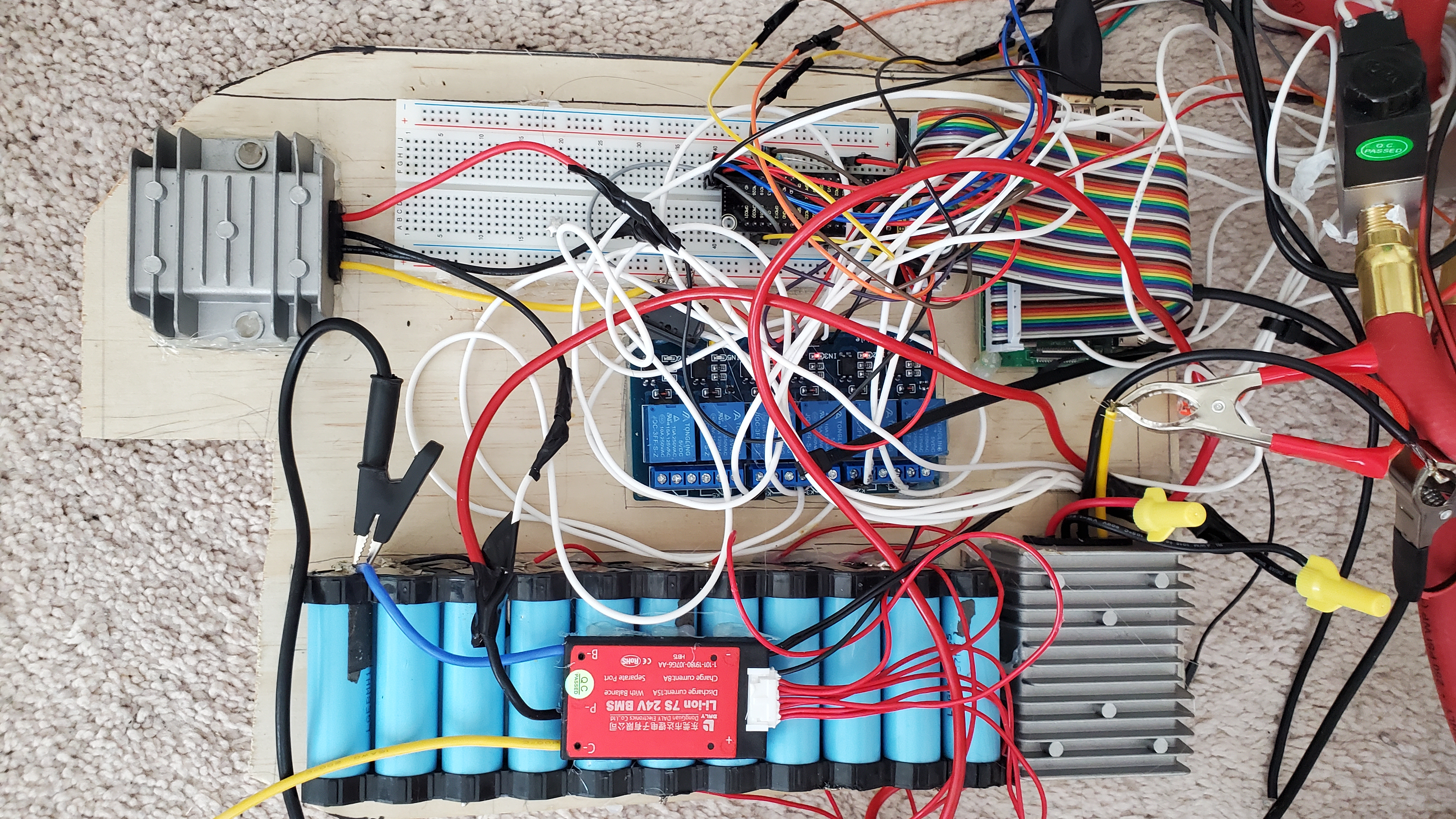

BATTERY/POWER:

The main design criteria was high energy density to minimize weight.

To achieve that, we leveraged the latest lithium-ion technology. By

placing the batteries (18650 cells) in a 7 series 3 parallel design,

we achieved a 250 Wh battery weighing 1kg. We then used a 24V

stepdown converter for the air compressor and microcomputer.

AIR DELIVERY SYSTEM:

The air delivery system actively pumps air into the pneumatic

cylinders. To control the flow of air, we developed a design that

had an air compressor pump air into an air tank that would branch

off into the two legs. On the legs, there would be two types of

solenoid valves that control the flow using signals they receive

from the computer to either let the air go through or not. The first

layer of solenoid valves works off Pulse Width Modulation to control

airflow through the tank (More details on P.W.M in the controls

section) while the second layer uses P.W.M. to exhaust air when

necessary.

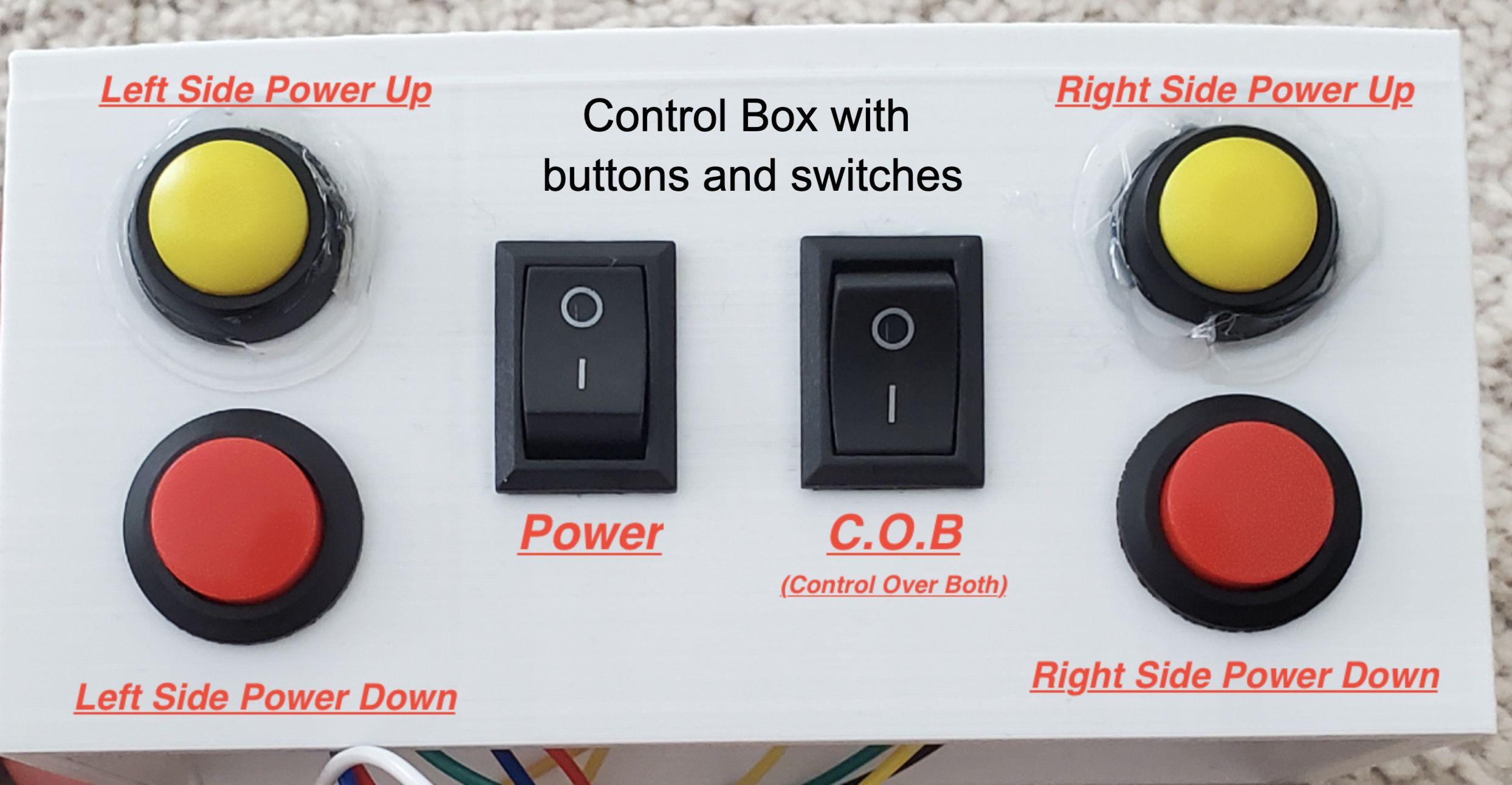

Control: (Software:

https://github.com/HOPE028/EMMAS)

The microcomputer's role is to analyze the user’s input and send

signals to the solenoid valves. To do so, the microcomputer sends 0

and 1 bits in the form of voltage to control the valve’s state. The

valve’s state is what decides if air goes through or not. Building

on top of that, we used the P.W.M framework for precise power

control. To utilize it, we send signal changes at a high frequency

to regulate the flow rate. All inputs are received from buttons and

switches. Through the inputs, the user can change what mode the

exoskeleton is in which affects how the exoskeleton behaves.

FRAME:

During the motion of squatting, the distance between the hip and

ankle reduces. By being able to manipulate the distance between

these two leg parts, we can mimic the leg’s movement. The pneumatic

cylinder allows us to do exactly that through the manipulation of

its own length by pumping air into its chambers when the ends are

attached to the ankle and hip.

When the pneumatic cylinder is compressing, however, it has the

ability to buckle the knee. In response, we created a frame for the

pneumatic cylinder to be attached to. The frame ensures that the

force from the pneumatic cylinder is limited to one degree of

freedom and that frame and pneumatic cylinder do not slide relative

to the body.

Testing: (Results In SO-WHAT Pictures)

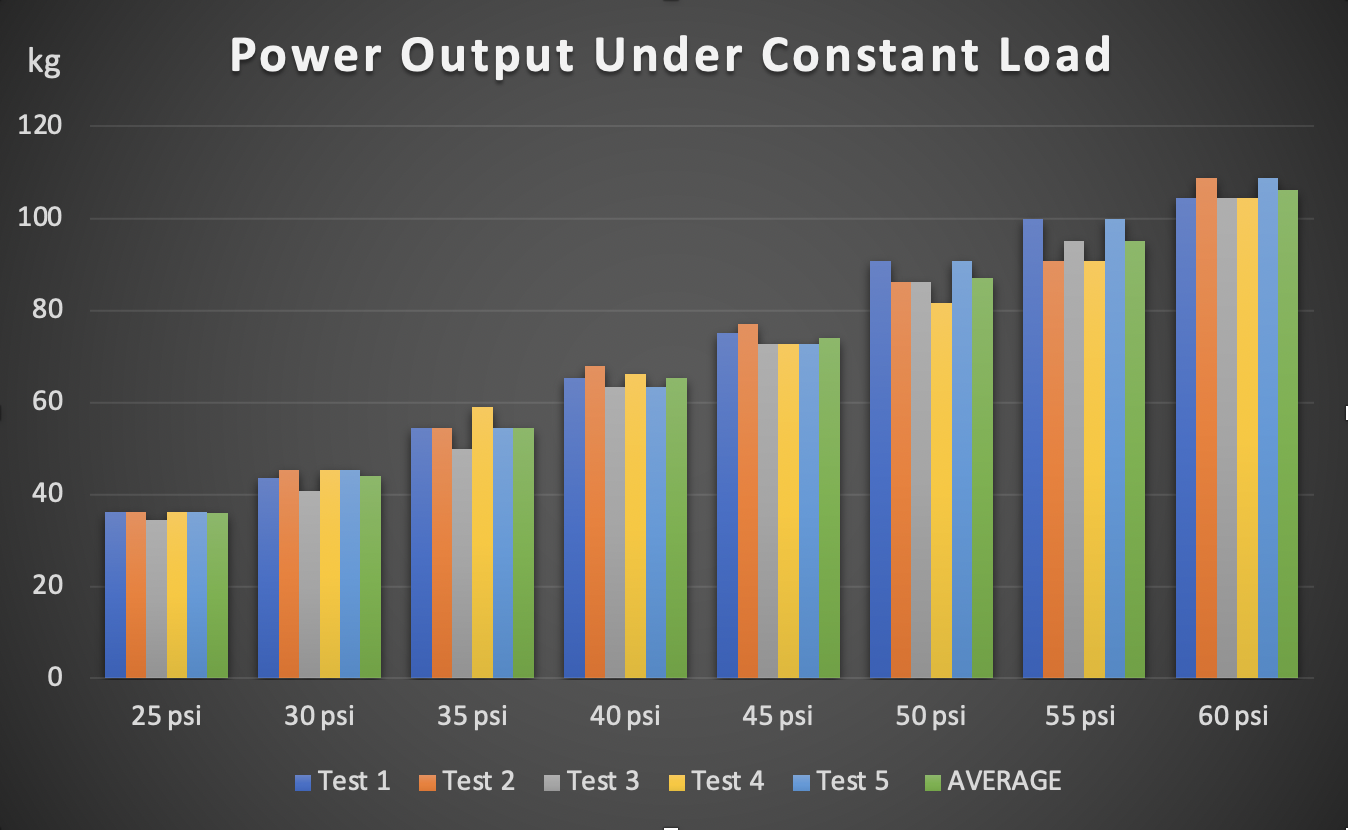

Power output under constant load:

We tested constant load performance by attaching one end of the

pneumatic cylinder to a scale and the other end to a solid base.

Through 40 different trials at 5 different pressures inside the

air-delivery system, we received performance data.

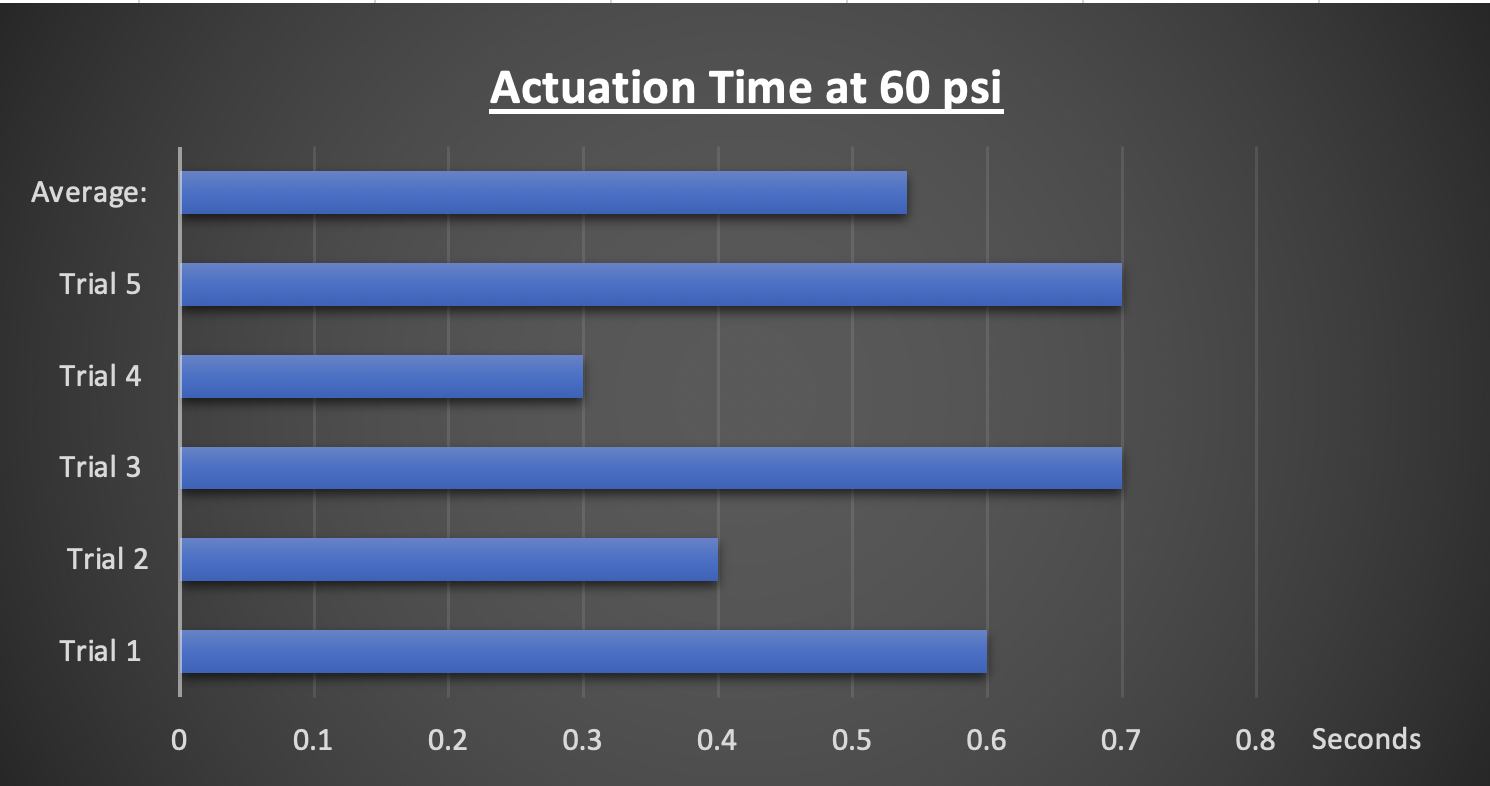

Actuation time:

We tested actuation time by setting the system at 60psi and

measuring the time between the user turning on the power and the

time it took for the system to start providing power.

The exoskeleton enhances the user's ability in ways we could not

have dreamed of. It provides incredible power at an explosive pace.

Providing up to 2940 newtons of force (at 150 psi theoretically) in

less than 0.54 seconds, the user can achieve tasks never thought to

be possible by humans. For testing equipment purposes, however, we

were never able to reach that pressure inside the chambers due to

safety concerns and air leakages stemming from prototyping. Instead,

we tested with lower pressure that a user would more realistically

use in real-life environments. The results were still very

impressive.

The first set of tests we did was reserved for seeing the power

output from the pneumatic cylinders when attached to the rest of the

system. The tests showed that when the system was running at 60 psi

(pressure inside the air delivery system), the pneumatic cylinders

could provide over 980N of force, more than enough force to lift

most users without the user's leg needing to do any work at all.

This would result in a substantial reduction of strain on the user's

body and give the user increased lifting capabilities.

Next, we tested the actuation time to test how fast a user could

receive the power of the exoskeleton. At 60 psi, the system would

take on average 0.54 seconds. That is fast enough so that the user

could carry on with their regular work pace while being aided by the

power of the exoskeleton.

The possibilities for improving the exoskeleton are endless. Some

notable optimizations would be a slightly modified frame with a more

ergonomic design, a more simple user interface that uses artificial

intelligence to predict the user's needs, and custom air compressors

and pneumatic cylinders to reduce weight and size.

We will work on these future improvements by using what we have

learnt over the span of this project such as consulting experts when

necessary, modelling more precise and thought out designs, and

having backup plans if ever something does not work out.

Research:

Taokang X., Yong Z., Ligang Q., Lin L., Chao G., (January 2022),

Weight-assisted exoskeleton knee joint plunger cylinder control

optimization,

https://www.sciencedirect .com/science/article/pii/S101 8363921001707

Fatai S., Hwa J. Y., Raja A. R. G, Norhafizan A., (November 2019),

Design and control of a wearable lower-body exoskeleton for

squatting and walking assistance in manual handling works,

https://www.sciencedirect .com/science/article/abs/pii/ S0957415819301059

Injury Data:

NSC, (April 2022), Top Work-related Injury Causes,

https://injuryfacts.nsc.org /work/work-overview/top-work- related-injury-causes/

Product Data: Wenzhou Ang Rui Machinery Co., Ltd, (April 2022)

https://www.alibaba.com/product-detail

/SC-series-Air- Cylinder-Double-Acting_ 60584234258. htmlspm=a2700.shop_plgr.414 13.30.3295631eXJSyQs

We must start by thanking our incredible parents (Saleh Khoshkebari,

Iran Atashgaran, Haiou Luo, Liang Yin) that had enough trust and

confidence in us to fund this entire project. Their unwavering

support will always be appreciated and we are so thankful for them.

Incredible thanks to Professor Eric Bibeau and Derek Neufeld for

their phenomenal material and resource help. They were a major part

of the material selection and fabrication of the frame.

C

Pi Thread

Wiring Pi